Are you seeking for 'magnetic particle'? Here you can find questions and answers on the topic.

Table of contents

- Magnetic particle in 2021

- Magnetic particle testing

- Magnetic particle testing (ndt)

- Magnetic particle testing questions answers

- Magnetic particle testing procedure

- Magnetic particle testing pdf

- Magnetic particle inspection kit

- Magnetic particle testing standard

Magnetic particle in 2021

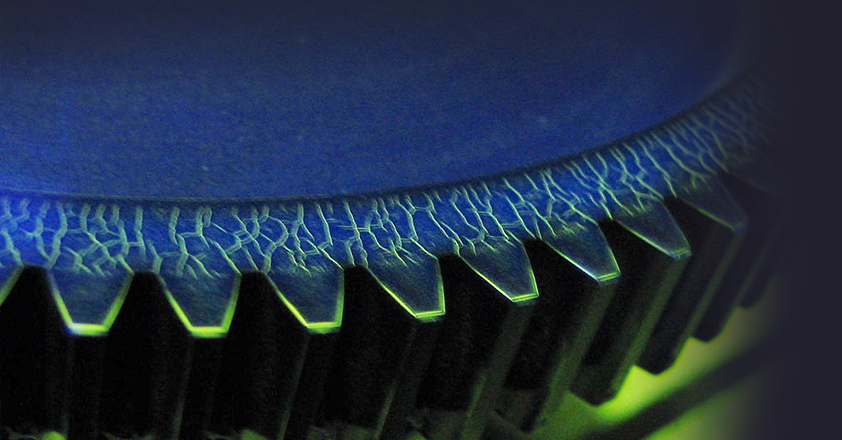

This picture demonstrates magnetic particle.

This picture demonstrates magnetic particle.

Magnetic particle testing

This image representes Magnetic particle testing.

This image representes Magnetic particle testing.

Magnetic particle testing (ndt)

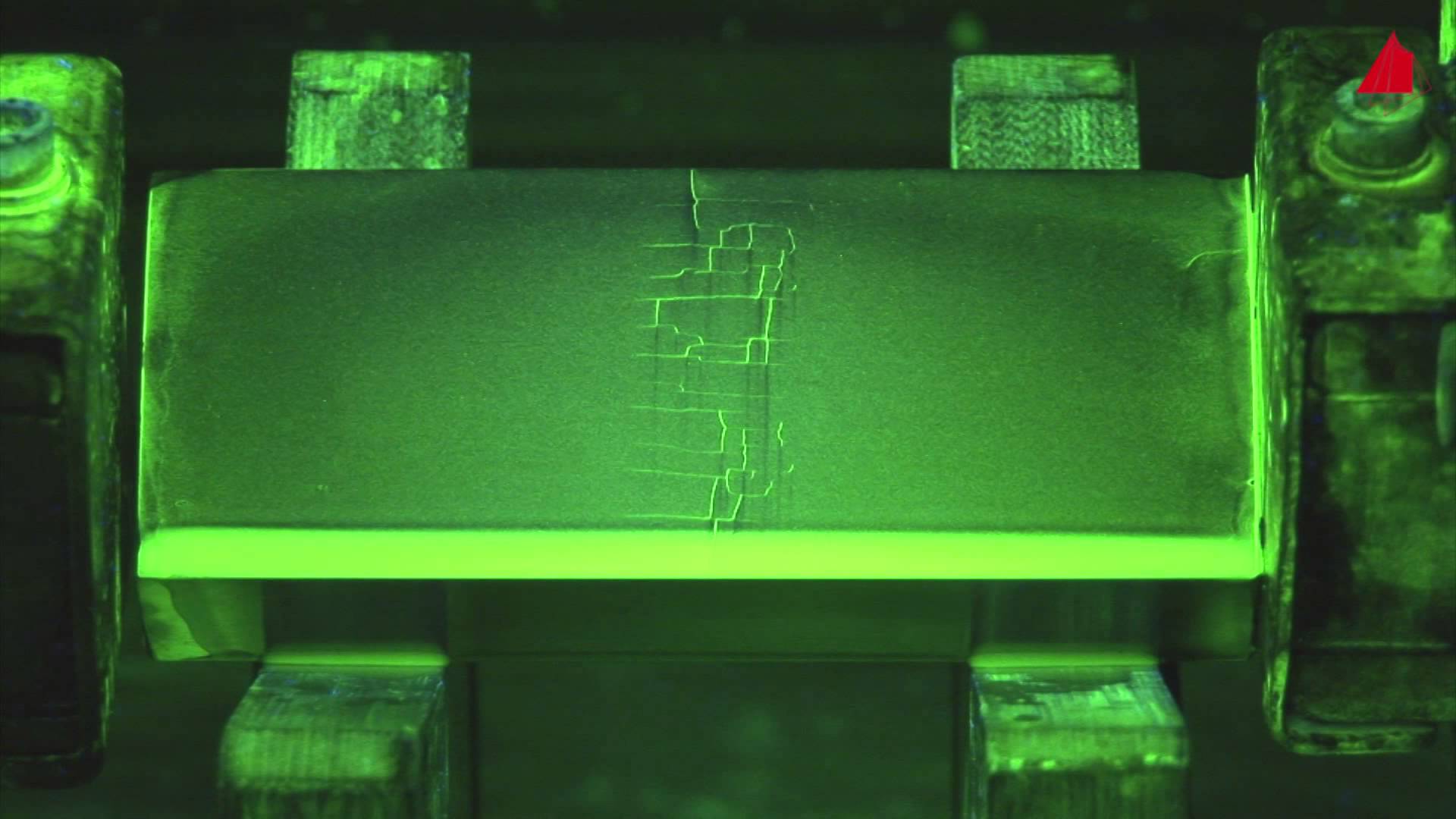

This image shows Magnetic particle testing (ndt).

This image shows Magnetic particle testing (ndt).

Magnetic particle testing questions answers

This picture illustrates Magnetic particle testing questions answers.

This picture illustrates Magnetic particle testing questions answers.

Magnetic particle testing procedure

This image representes Magnetic particle testing procedure.

This image representes Magnetic particle testing procedure.

Magnetic particle testing pdf

This picture illustrates Magnetic particle testing pdf.

This picture illustrates Magnetic particle testing pdf.

Magnetic particle inspection kit

This image illustrates Magnetic particle inspection kit.

This image illustrates Magnetic particle inspection kit.

Magnetic particle testing standard

This image representes Magnetic particle testing standard.

This image representes Magnetic particle testing standard.

Where are most of the magnetic particles located?

If the material is sound, most of the magnetic flux is concentrated below the material’s surface and the particles follow the induced magnetic field ( Shull, 2002; TWI, 2008).

What is the process of magnetic particle testing?

Magnetic Particle Testing, also known as Magnetic Particle Inspection (MPI) is the process whereby a component is magnetised to produce lines of magnetic flux within the component.

How does a magnetic particle respond to a drive field?

Particles that are in the FFR respond to the drive field, but those which are far away from the FFR and saturated by the bias field do not. The particles in the FFR give a periodic magnetization response which induces a voltage in a receive coil.

How are magnetic particles used in NDI inspection?

Magnetic particle inspection is a simple NDI method used to detect cracks at the surface of ferromagnetic materials such as steels and nickel-based alloys. The inspection process begins with the magnetisation of the component. The surface is then coated with small magnetic particles, which is usually a dry or wet suspension of iron filings.

Last Update: Oct 2021